Printed circuit boards form the backbone of modern electronics, supporting everything from consumer devices to industrial systems. PCB manufacturing in Singapore has gained strong recognition due to its focus on precision, quality control, and advanced production standards. Knowing the process, from initial design to final assembly, can provide businesses and engineers with a clear understanding of what to expect when producing a PCB board in Singapore.

Design and Engineering Preparation

The manufacturing process begins with design and engineering, where functionality and reliability take priority. Engineers translate circuit requirements into detailed schematics and layouts, ensuring the PCB board meets electrical, thermal, and mechanical specifications. At this stage, design decisions affect manufacturability, cost efficiency, and long-term performance. Factors such as layer count, trace width, material selection, and component placement must align with production capabilities.

Design teams in Singapore often work closely with manufacturers to review layouts before fabrication begins. This collaboration reduces errors, shortens production timelines, and improves yield rates. Companies involved in PCB manufacturing in Singapore emphasise design-for-manufacturing checks to identify issues early. When engineers address potential risks upfront, they avoid costly revisions during fabrication and assembly.

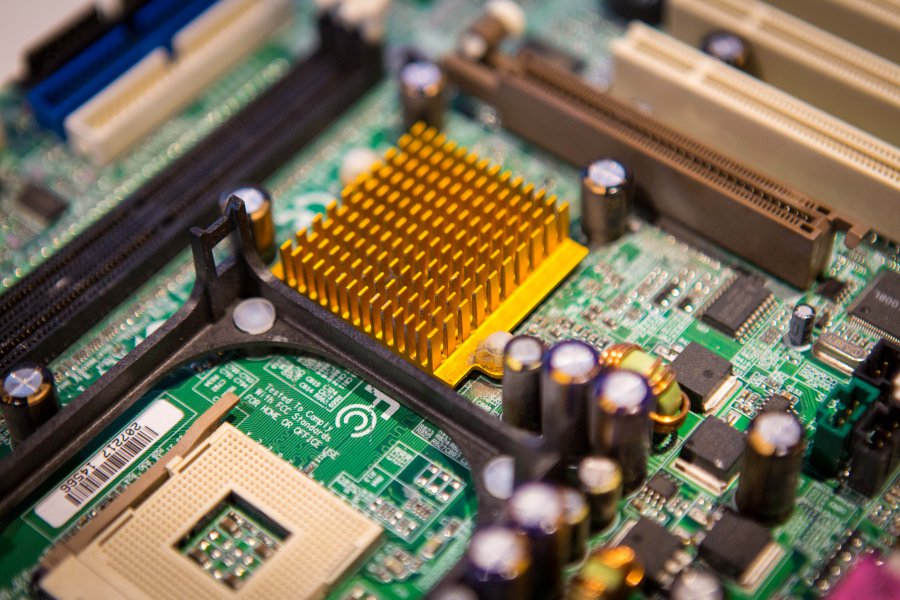

PCB Fabrication and Board Production

Once the design is finalised, fabrication begins with the production of bare boards. This stage involves layering copper-clad laminates, drilling precise holes, and forming conductive pathways according to design specifications. Manufacturers use advanced equipment to maintain tight tolerances, which is essential for high-density and multi-layer boards. The quality of this stage directly influences signal integrity and overall board reliability.

In Singapore, facilities follow strict quality standards to ensure consistency across batches. Automated optical inspections and electrical testing help identify defects before the boards proceed further. Businesses sourcing a PCB board in Singapore benefit from strong process controls and compliance with international manufacturing standards. These measures support industries that demand precision, including medical technology, telecommunications, and industrial automation.

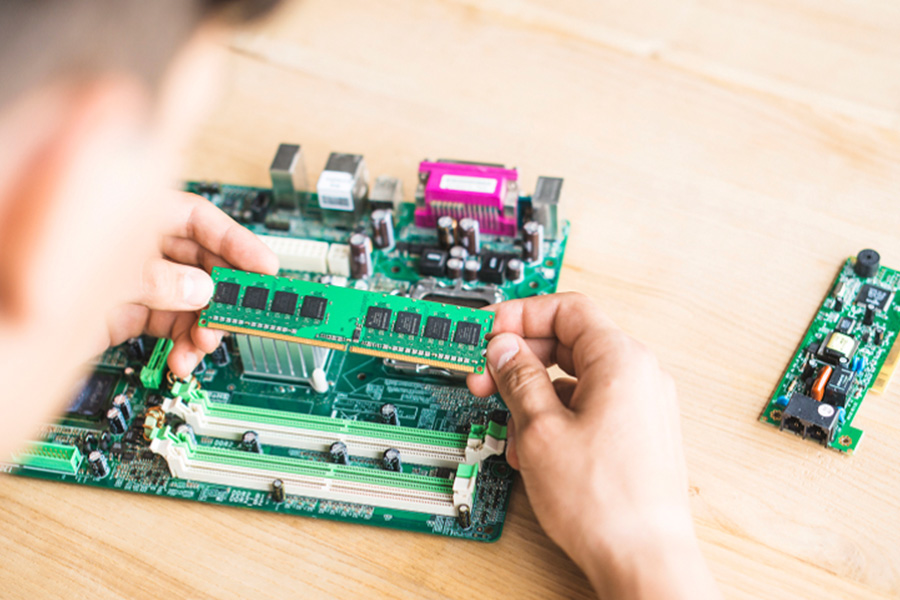

Component Sourcing and PCB Assembly

After fabrication, the focus shifts to assembly, where components are mounted onto the board. Surface mount technology and through-hole assembly processes place components accurately and securely. Manufacturers prioritise component compatibility and sourcing reliability to maintain production efficiency. This stage requires careful coordination to ensure correct orientation, soldering quality, and mechanical stability.

Many providers of PCB manufacturing in Singapore offer integrated assembly services to streamline production. This approach reduces handling risks and improves turnaround time. Companies such as MPN Tech support clients by managing both fabrication and assembly under one roof, helping businesses maintain quality control and simplify supply chains. Integrated services also improve accountability and communication throughout the production cycle.

Supply Chain Management and Lead Time Considerations

Effective supply chain management is crucial in PCB manufacturing in Singapore. Manufacturers must coordinate raw material sourcing, component availability, and production scheduling to meet project deadlines. Disruptions in laminate supply or electronic components can affect delivery, particularly for complex or high-volume orders. Manufacturers reduce these risks by working with established suppliers and maintaining structured procurement processes.

Lead time transparency also matters when sourcing a PCB board in Singapore. Clear timelines covering fabrication, assembly, testing, and delivery allow clients to plan product launches and system integration accurately. Manufacturers that communicate lead times clearly and adapt quickly to changes help businesses manage expectations and minimise operational risks in fast-moving electronics markets.

Testing, Inspection, and Final Assembly

Testing verifies board performance before final delivery. Manufacturers conduct functional tests, in-circuit testing, and visual inspections to confirm that each PCB board in Singapore meets design requirements. These tests detect faults such as short circuits, incorrect component placement, or soldering defects. A thorough inspection ensures the final product performs reliably in real-world applications.

After testing, final assembly prepares the board for integration into finished products. This may include enclosure fitting, cable connections, or system-level integration. Manufacturers place strong emphasis on documentation and traceability during this phase. Clear records support quality assurance and help clients meet regulatory or customer requirements, especially in regulated industries.

Conclusion

PCB manufacturing in Singapore follows a structured process that prioritises accuracy, efficiency, and quality from design to final assembly. By understanding each stage, businesses can make informed decisions when sourcing a PCB board in Singapore. Strong collaboration, advanced technology, and rigorous testing standards continue to position Singapore as a trusted hub for PCB production.

Contact MPN Tech for dependable PCB manufacturing and assembly solutions that meet your technical and production requirements.